Our History

Nidco was established in 1948, in the city of Ramla. It initially manufactured products for the medical industry, such as incubators, sterilizers and vibrators. In the 1950s, it was purchased by Mr. David Nissan, a worker in the factory who began his career as a youth apprentice at the shop. The workshop started out in a small building, and grew, under David’s management and according to his vision to its current day size which is currently over 7000 square meters.

In the early years Nidco performed major engineering and mechanical work for the most part of developing Israel’s industrial plants and factories. In the local industrial community he is appreciated and merited to this day!

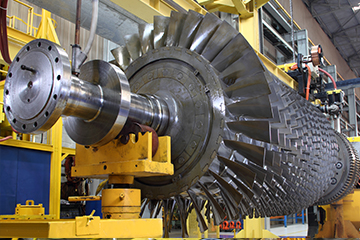

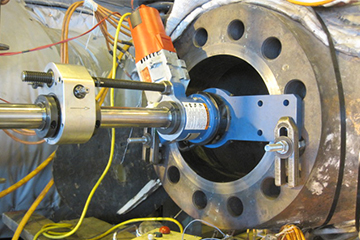

Nidco developed strong capabilities in rotating equipment and from there the transition to specializing in heavy rotating equipment and machine overhaul was seamless.

Our core business shifted towards providing in-house and on-site mechanical and machining services for heavy rotating equipment and plant overhaul for all the strategic and critical production lines in Israel such as an “Nesher” Cement (Ramla and Har-Tov plants), The Dead Sea Works, ICL, Oil refineries, Energy sector, desalination plants, Oil & Gas industry and basically all the heavy equipment operators and end users in Israel